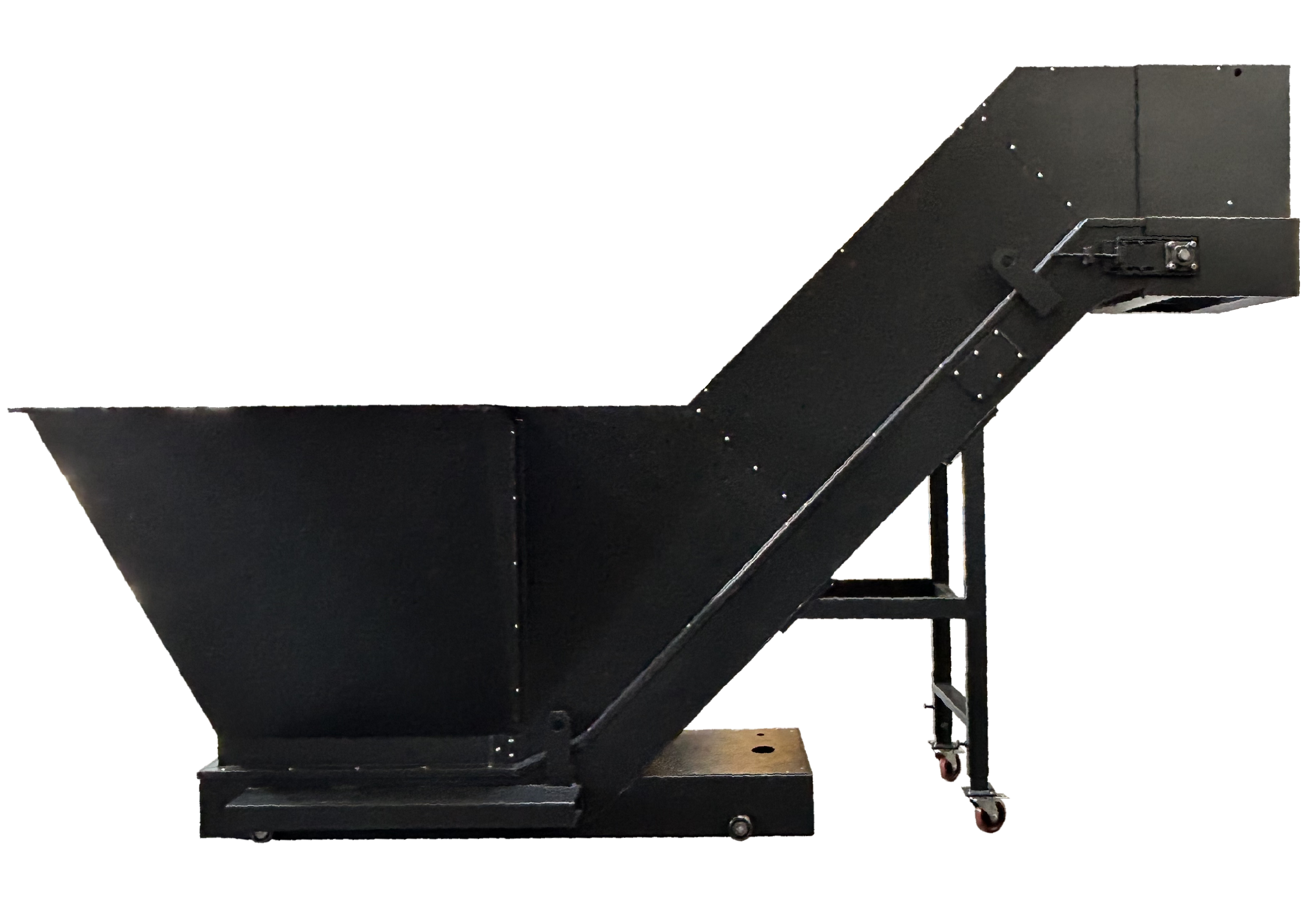

Metal line loading and unloading belts

Conveyor belt IL500S

Conveyor belt IL500S for swarf loading for briquetting machine without liquid collection and recovery tank.

TECHNICAL CHARACTERISTICS:

- large hopper for material loading;

- painted steel frame with reinforced sheet metal profiles;

- front support legs with feet;

- rear support wheels;

- welded steel side chain guides;

- painted steel side rails and hopper;

- steel shutters and flights;

- gear motor keyed directly onto the drive shaft.

Operation

A geared motor controls the operation of the belt to ensure adequate material dosage to the briquette press

The advantages of our products

Discover the qualities of our briquetting presses

The qualities

Over 40 years of experience and 18,000 machines sold.

Technical data

| Reduction motor power | kW | 0.75 |

| Voltage | Volts / HZ | 400 / 50 |

| Facchini | H (mm) | 40 |

| Tape | L (mm) | 500 |

| Loading hopper dimensions | L (mm) P (mm) H (mm) | 1350 1238 1000 |

| Maximum height at discharge | H (mm) | 2950 |

| Weight | Kg | 850 |