Special line briquetting presses

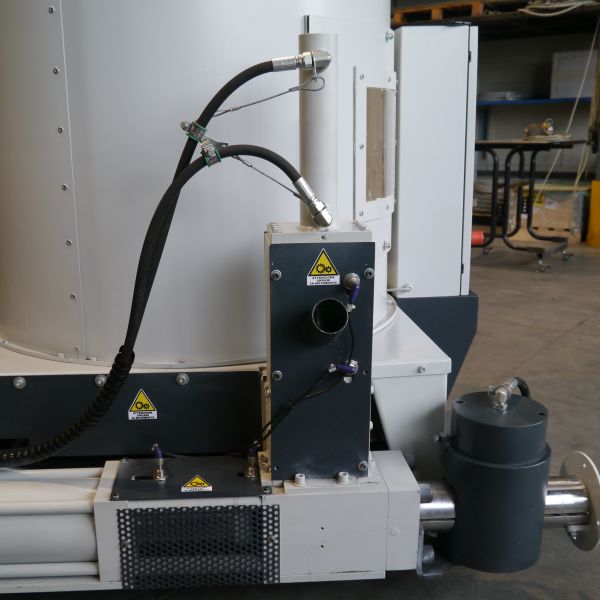

HITECH ELP 60 briquetting press

The product is for small- and medium-sized industrial and farming companies.

This is a hydraulic briquetting press for recycling processing scrap for its reuse and regeneration. More specifically, very bulky scrap consisting of chips of wood, cotton, textiles, polyurethane, polystyrene, polyester, polypropylene, hay, straw, alfalfa, animal feed, etc., with a humidity ranging between 8% and 17% are transformed into cylindrical briquettes with variable diameter (depending on the briquetting press), resulting in a sensible reduction in volume 1/5–1/30 depending on the type of material and up to 150 times (as in the case of polystyrene). The briquetting press can be applied to silos or filtering batteries indoors or outdoors.

Operation

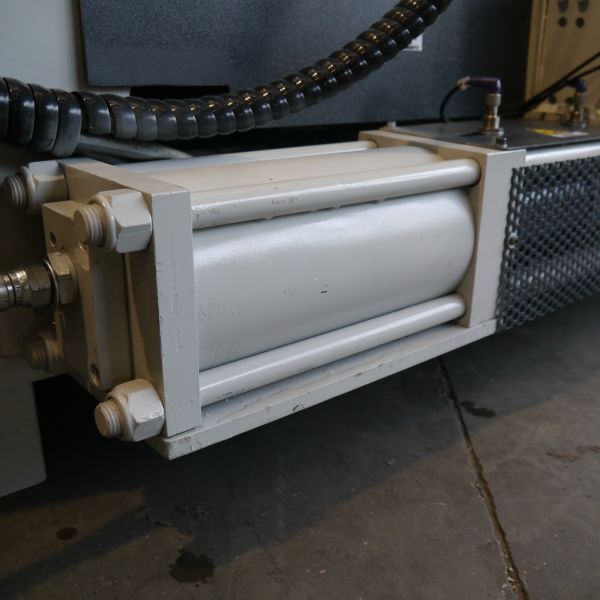

It is based on a mechanical and hydraulic cycle of high-pressure compacting. A material containment hopper is fastened to a loading bed consisting of a radial loader, which by rotating doses the material to a screw which, in turn, feeds it to a box controlled by a hydraulic cylinder that pre-compresses the material before it reaches the compression chamber. A special hydraulic compression cylinder then compresses the material in the sleeve-extrusion pipe unit.

Discover the qualities of our briquetting presses

The qualities

Technical characteristics

Technical data

| Output | Kg/h | 20÷ 85 |

| Briquette | Ø mm | 60 |

| Box cylinder | Ø mm | 50 |

| Compression cylinder | Ø mm | 140 |

| Compression cylinder pressure | Kg/cm2 | approx. 800 |

| Pump motor power | kW | 5.5 |

| Voltage | Volt/Hz | 400 / 50 |

| Hopper | Ø mm | 1000 |

| Briquetting press dimensions | L (mm) W (mm) H (mm) | 1300 2150 1400 |

| Weight | Kg | 980 |