Products

Save resources and increase profit

METALPRESS Metal briquetting presses

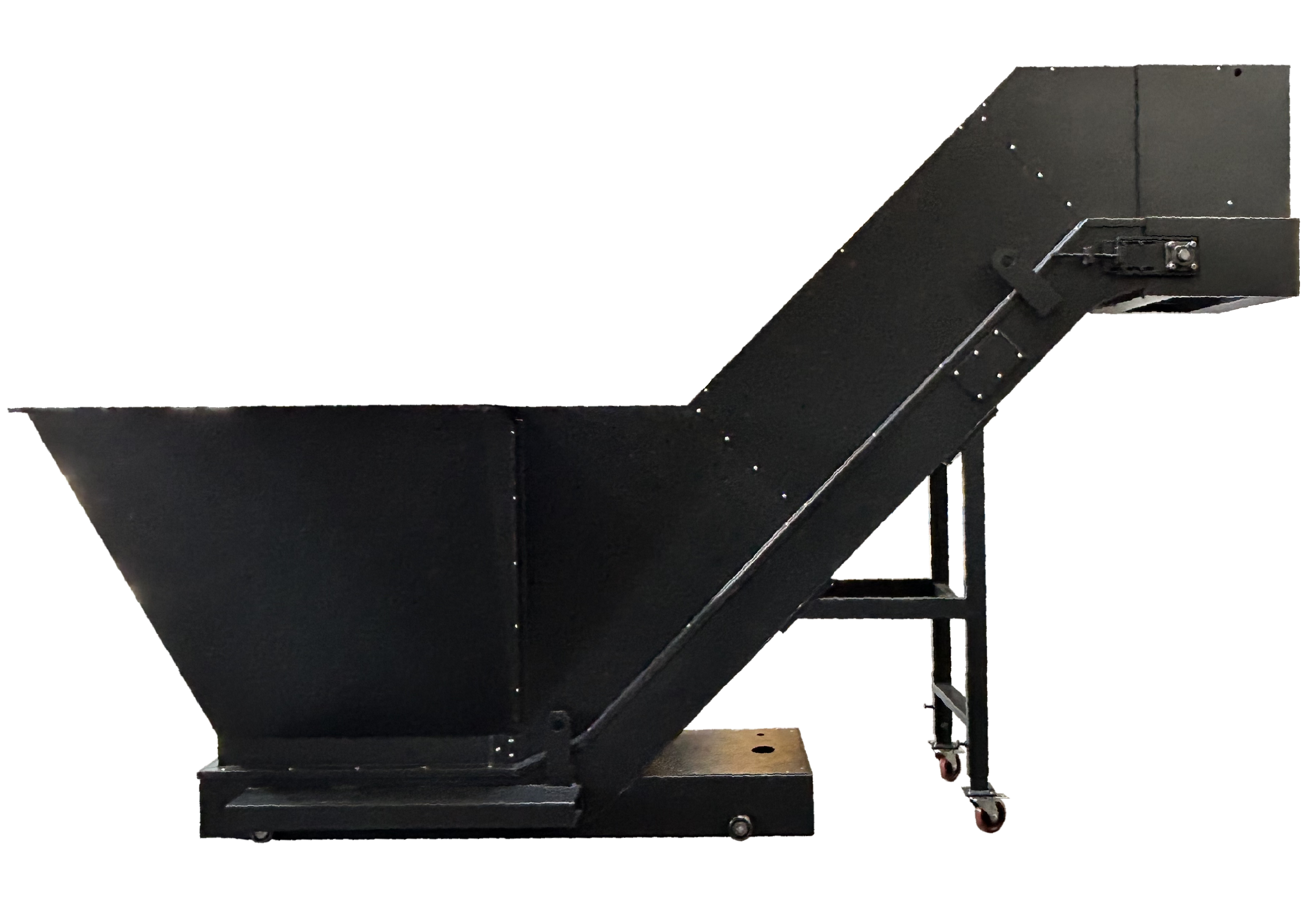

Metal line loading and unloading belts

The advantages of our products

Reduction in volume –90%

Briquettes allow for sensible reduction in volume (depending on the type of material) due to their high pressure compactness rather than the chips. They make work environments considerably more organised and efficient. You can use new spaces to store products and for the production lines.

Reduction in volume –90%

Lower handling/transport costs –80%

The briquettes ensure easy and practical handling, thus reducing internal and external transport costs (use of the forklift truck and, consequently, the time operators dedicate to collecting scrap).

Lower handling/transport costs –80%

Lower recycling costs –70%

The lower transport costs for briquettes have a direct impact on the sales margin at the collection facilities and can represent a valuable source of income.

Lower recycling costs –70%

Lower environmental impact

Briquettes allow for reducing the environmental impact due to the conditions and state of the container or collection facilities, which are often not in a good state.

Lower environmental impact

Lower environmental pollution –70%

Thanks to briquettes, the number of container voyages can be drastically reduced, consequently less fumes released into the atmosphere for transporting scrap to the collection facilities.

Lower environmental pollution –70%

Increase in commercial value +50% and yield during melting +90%

Briquettes intended for foundries have a higher commercial value compared to chips, as during the melting phase their yield increases sensibly depending on the type of material. Their essential characteristic lies in their extremely high compacting pressures, which makes them qualitatively better compared to simple chips exposed to the elements and subject to oxidation, reductions and shrinkages. The chips containing cutting fluids and requiring pre-treating, once briquetted, can be loaded immediately into the melting furnaces and crucibles, resulting in considerably shorter times, significant energy saving and a considerable reduction in the risk of particle deposits on the walls of the furnaces and crucibles.

Increase in commercial value +50% and yield during melting +90%

Recovery of any oil present +20%

Metal shavings can contain a significant amount of high quality and very expensive oil. During pressing it is possible to recover approximately up to 20% (with further particular filtering treatments), considerably reducing the purchase cost of the new oil.

Recovery of any oil present +20%