Special line briquetting presses

Special 200S briquetting press

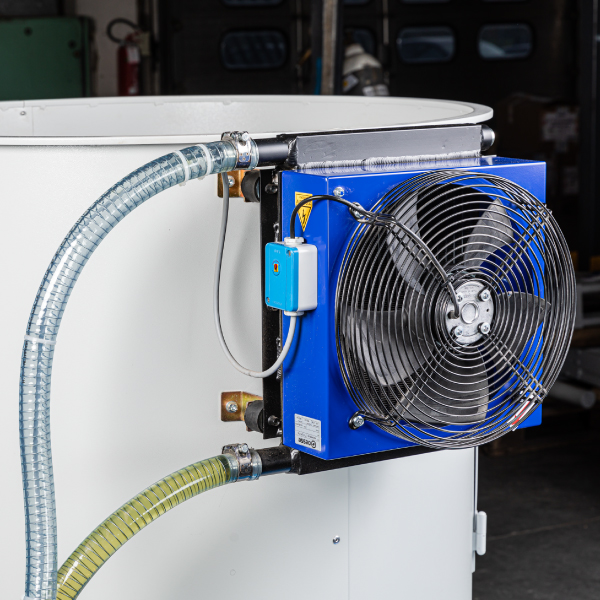

It is an oleodynamic machine designed to recycle and compact waste, natural and synthetic scrap and other very bulky and light materials from industrial processing (optimum moisture content must be between 8%-17%) into cylindrical briquettes with considerable advantages. It can also be applied to silos or filter batteries indoors or outdoors.

Operation

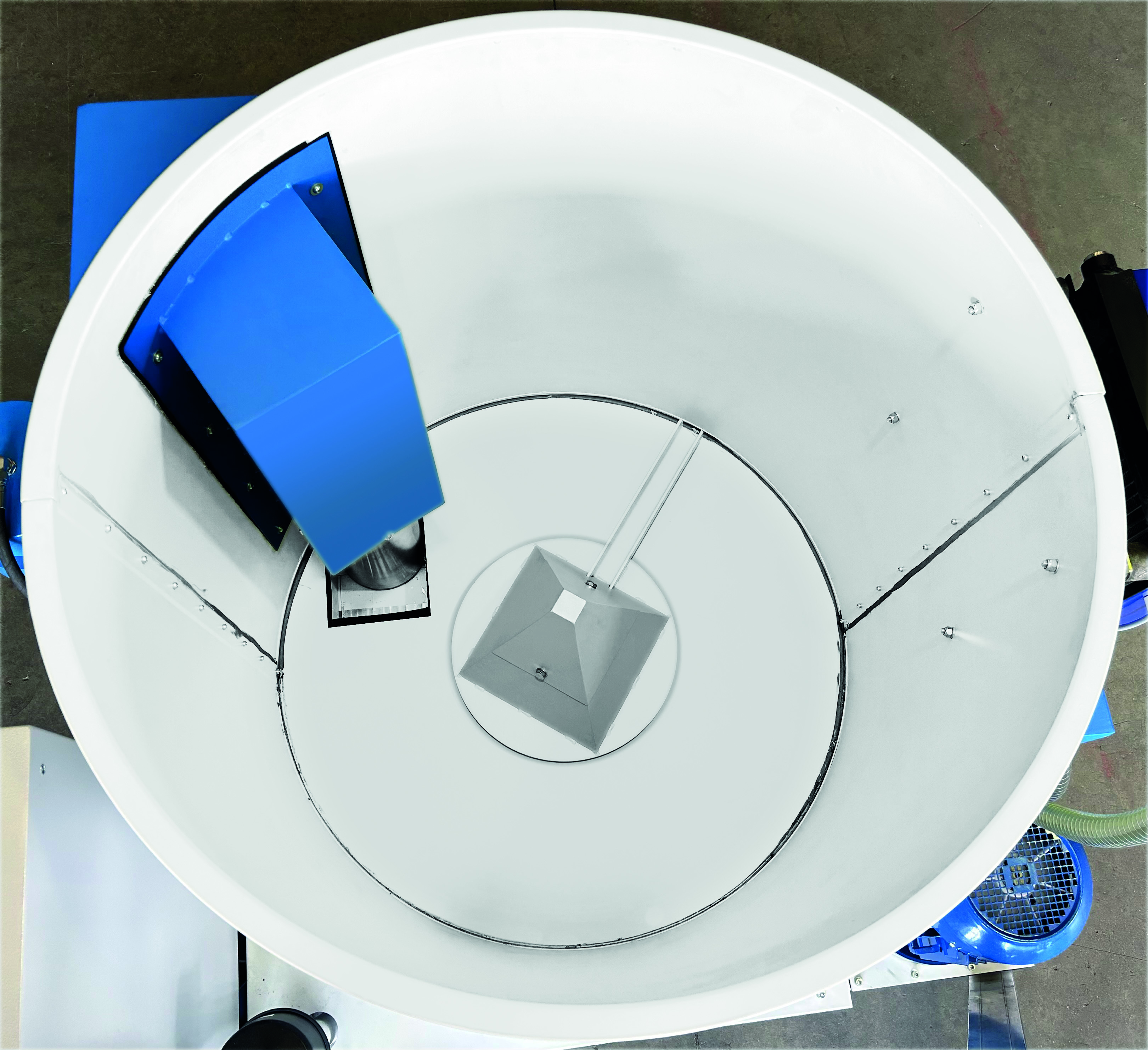

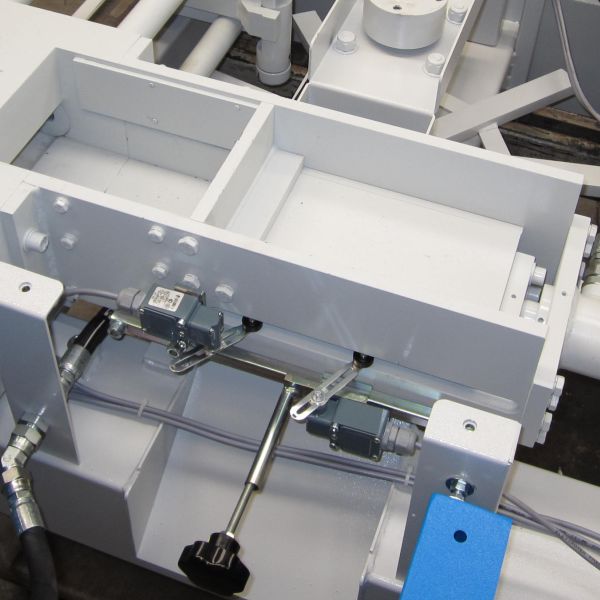

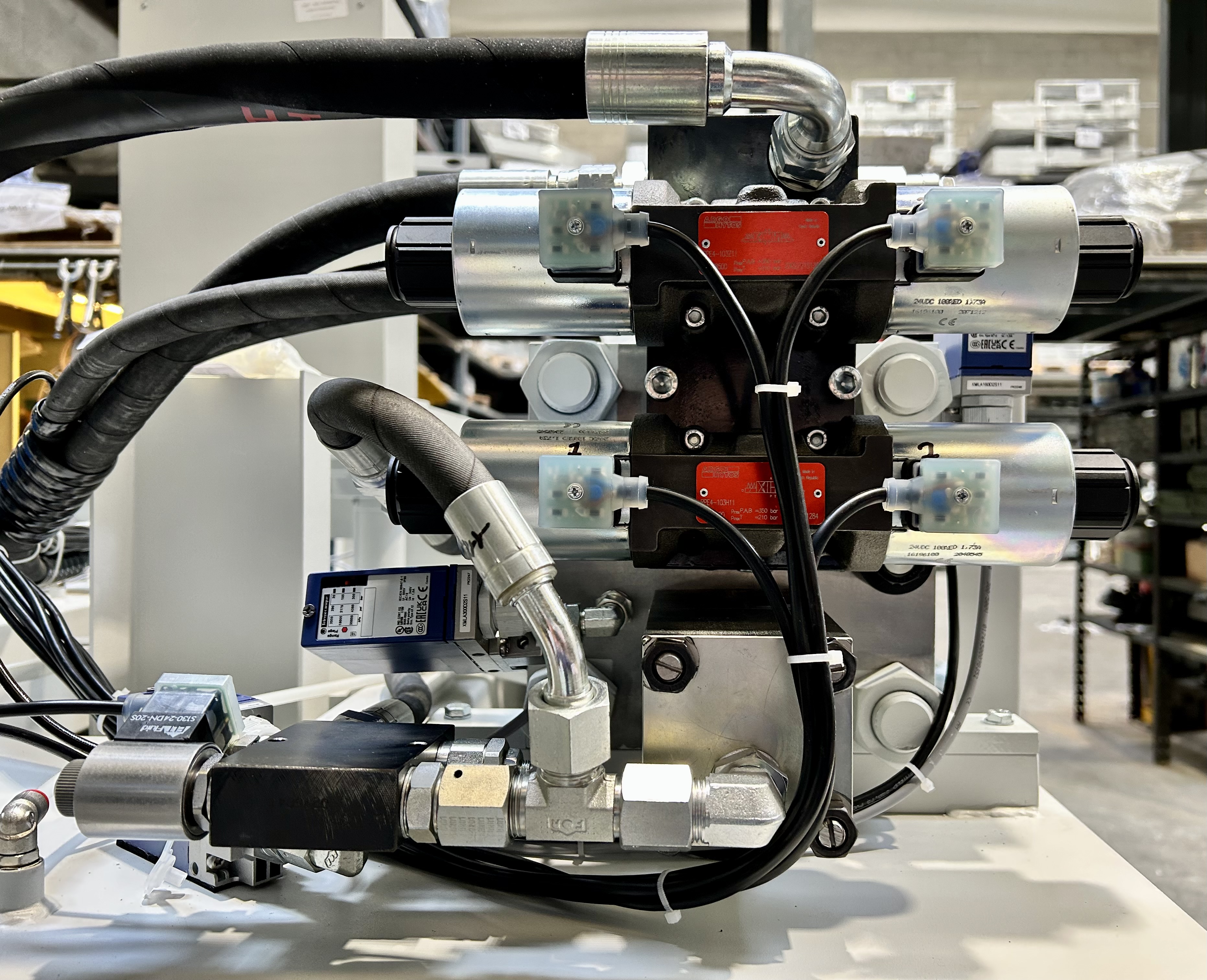

Operation is based on a mechanical and hydraulic high-pressure compaction cycle. A material containment hopper is attached to a platform consisting of an agitator which, by rotating, ensures the feeding of material to a fixed chamber in which a drawer driven by an oleodynamic cylinder runs, with the function of dosing the material into a compaction chamber. A special pneumatic cylinder has the function of conveying the bulky and light material vertically into the fixed chamber of the drawer, thereby promoting its filling. A hydraulic compacting cylinder then compresses the material in the compacting chamber to form the briquette. A vice equipped with an oil-dynamic cylinder and a quill handles the sliding and ejection of the briquette.

Discover the qualities of our briquetting presses

The qualities

Technical characteristics

Technical data

| Approximate output | Kg/h | 70 ÷ 140 |

| Briquette | Ø mm | 70 |

| Box cylinder | Ø mm | 60 |

| Compression cylinder | Ø mm | 180 |

| Maximum compacting pressure | bar | 800 |

| Pump motor power | kW | 9.2 |

| Total installed power | kW | 10.5 |

| Voltage | Volts/HZ | 400 / 50 |

| Hopper | Ø mm | 1000 |

| Briquetting press dimensions | L (mm) P (mm) H (mm) | 1200 1838 1467 |

| Weight (kg) | Kg | 1230 |